Configuration Files

Configuration files are described in the YAML format. YAML is a human-readable data serialization format. It is commonly used for configuration files and in applications where data is being stored or transmitted. For more information on YAML, see the YAML website.

Sensor Configuration

The sensor configuration file is defined by the competitor and describes the location of sensors added to the competition environment.

Listing 11 shows an example of a sensor configuration file with one of each of the different possible sensors.

The first field in the yaml file is robot_cameras. This is an optional field in the sensor configuration file. If this field is not present in the file, cameras will not be activated. Alternatively the active field can be used to enable or disable a camera for either robot. Last the type field should be either rgb or rgbd.

The second field in the configuration file is static_sensors. This field should contain all the static sensors that the competitor wants to add. Static sensors each have four fields:

A name (e.g.

right_bins_camera). This name has to be unique among all sensors in the same configuration file.A type (e.g.

rgb_camera). This type has to be one of the following types described in the section Static sensors.A pose defined in the world frame:

A position

xyz. This should be a list with three elements representing the x, y, and z coordinates for the sensor origin.An orientation

rpy. This should be a three element list containing the roll, pitch and yaw of the sensor using this convention . The orientation should be defined in radians using either floating-point values or with thepiconstant (pi,pi/2,pi/4, etc).

A toggle for visualizing the sensor field of view

visualize_fov. This field is optional and if not present the default isfalse.

robot_cameras:

floor_robot_camera:

active: true

type: rgb

ceiling_robot_camera:

active: true

type: rgbd

static_sensors:

breakbeam_0:

type: break_beam

visualize_fov: true

pose:

xyz: [-0.35, 3, 0.95]

rpy: [0, 0, pi]

proximity_sensor_0:

type: proximity

visualize_fov: true

pose:

xyz: [-0.573, 2.84, 1]

rpy: [pi/2, pi/6, pi/2]

laser_profiler_0:

type: laser_profiler

visualize_fov: true

pose:

xyz: [-0.573, 1.486, 1.526]

rpy: [pi/2, pi/2, 0]

lidar_0:

type: lidar

visualize_fov: false

pose:

xyz: [-2.286, -2.96, 1.8]

rpy: [pi, pi/2, 0]

rgb_camera_0:

type: rgb_camera

visualize_fov: false

pose:

xyz: [-2.286, 2.96, 1.8]

rpy: [pi, pi/2, 0]

rgbd_camera_0:

type: rgbd_camera

visualize_fov: false

pose:

xyz: [-2.286, 4.96, 1.8]

rpy: [pi, pi/2, 0]

basic_logical_camera_0:

visualize_fov: false

type: basic_logical_camera

pose:

xyz: [-2.286, 2.96, 1.8]

rpy: [pi, pi/2, 0]

Trial Configuration

The trial configuration file contains all the information that the AM uses to run a given trial. This includes part and kit tray information, orders, and challenges. Listing 12 shows an example of a trial configuration file with all of the possible fields.

Fields

time_limit, Float

The time limit is a positive floating point number that represents the number of seconds that the competitor has to complete the trial. At the end of the time limit the competition will end automatically.

kitting_trays, Dictionary

This section defines the kit trays that will be spawned onto the kit tray stations at the start of simulation.

tray_ids,List: The IDs of the all the trays to be spawned (0-9). Several trays can have the same ID.

slots,List: The slots on the kitting tray station where the trays will be spawned (kts1: 0-3, kts2: 4-6). Slots must be unique.Note

The

tray_idsandslotslists should be the same length.

assembly_inserts, Dictionary

This section defines the rotation for each of the assembly station inserts.

as{n},FloatorString: Rotation in radians of assembly insert n (1-4). Pi strings can be used.

parts, Dictionary

This section defines all the parts that will be spawned into the environment.

agvs,Dictionary: Parts that will placed directly onto the AGV at the start of the simulation. These parts are directly related to the assembly order and will be filled out automatically based on the assembly order if using the trial_generator.

agv{n},Dictionary: The AGV that will have parts (n: 1-4). Multiple agvs may have parts.

tray_id,Integer: The ID of the kitting tray (0-9) that will be placed on the AGV. Parts on AGVs should always be placed onto a kit tray.

parts,List: Parts that will be spawned on the tray.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

quadrant,Integer: The quadrant of the kit tray the part will be spawned onto (1-4).

rotation,FloatorString: The rotation of the part in radians. Pi strings can be used.

bins,Dictionary: Parts that will be placed into the bins at the start of the simulation.

bin{n},Dictionary: The bin that will have parts (n: 1-8). Multiple bins may have parts.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

rotation,FloatorString: The rotation of the part in radians. Pi strings can be used.

flipped,Boolean: Whether the part will be flipped. Iftruethe z-axis of the part will face down instead of up.

slots,List: The slots of the bin that this part can be found (1-9). Each slot should be unique for a given bin.

conveyor_belt,Dictionary: Parts that will be spawned onto the conveyor when the competition is started. The cycle of parts will be repeated after all parts are spawned, up until the competition ends.

active,Boolean: Whether the conveyor is active. This toggle is mostly used for testing to enable or disable the conveyor without removing all the parts.

spawn_rate,Integer: The time in seconds between parts spawned on the conveyor.

order,String: Either'sequential'where all parts of the same type will appear before the next type, or'random'where the parts will come out in a random order.

parts_to_spawn,Dictionary: This is a list of part lots that will be found on the conveyor.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

number,Integer: The number of parts spawned with the selectedtype,color,offset,flipped, androtation.

offset,Float: The position on the conveyor belt. Positive offset is further from the bins and negative offset is closer to the bins. This value should be between -1.0 and 1.0.

flipped,Boolean: Whether the part will be flipped. Iftruethe z-axis of the part will face down instead of up.

rotation,FloatorString: The rotation of the part in radians. Pi strings can be used.

orders

id,String: Unique identifier for each order. String with a length of 8 characters.

type,String: Determines the type of order. Possible values are'kitting','assembly', and'combined'.

announcement,Dictionary: Determines under what condition the order will be announced.

priority,Boolean: Determines whether the order is a regular order,false, or a high priority order,true.

task_info: The information for the task based on the ordertype. Eitherkitting_task,assembly_task, orcombined_task

kitting_task,Dictionary: This is only used iftypeis set to'kitting'.

agv_number,Integer: The agv number for the agv used in the kitting order.

tray_id,Integer: The tray ID which will be placed on the agv for the kitting order.

destination,String: The destination for the agv after all parts are placed on it. Destination should always be set towarehouse.

products,List: The list of parts to be placed on the agv for the kitting order. Maximum of four.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

quadrant,Integer: The quadrant of the kitting tray which the part should be placed on.

assembly_task,Dictionary: This is only used iftypeis set to'assembly'.

agv_number,List: List of agvs which will be used for the assembly order.

station,String: The assembly station where the assembly of the breifcase will take place.

products,List: The list of parts to be assembled in the breifcase. Maximum of four.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

assembled_pose,Dictionary: The position and orientation of the part relative to the breifcase frame.

xyz,List: A list of position coordinates of the part assembly pose relative to the breifcase frame.

rpy,List: A list of orientation values of the part assembly pose relative to the breifcase frame.

assembly_direction,List: A unit vector in the breifcase frame.

combined_task,Dictionary: This is only used iftypeis set to'combined'.

station,String: The assembly station where the assembly of the breifcase will take place.

products,List: The list of parts to be assembled in the breifcase. Maximum of four.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

assembled_pose,Dictionary: The position and orientation of the part relative to the breifcase frame.

xyz,List: A list of position coordinates of the part assembly pose relative to the breifcase frame.

rpy,List: A list of orientation values of the part assembly pose relative to the breifcase frame.

assembly_direction,List: A unit vector in the breifcase frame.

challenges

dropped_part,Dictionary: Adds a dropped part challenge to the environment.

robot,String: Determines which robot will drop the part. Options are'floor_robot'or'ceiling_robot'.

type,String: Determines the type of part that will be dropped ('sensor','regulator','pump', or'battery').

color,String: Determines the color of part that will be dropped ('red','blue','green','orange', or'purple').

drop_after,Integer: Determines the index of the part to drop after. For example, ifdrop_afteris set to 2, the 3rd part the robot successfully picks will be dropped.

delay,Float: Drops the part after the specified delay.

robot_malfunction,Dictionary: Adds a robot malfunction challenge to the environment.

duration,Float: Determines how long the robot malfunction will last.

robots_to_disable,List: List of robots that can be disabled. Options are'floor_robot'or'ceiling_robot'.

announcement: One of the three announcement conditions

time_condition,Float: After this amount of time has passed, the specified robot(s) will malfunction.

part_place_condition,Dictionary: The robot malfunction starts after a part of a specific type and color is placed on a specified agv.

type,String: The type of the part ('sensor','regulator','pump', or'battery').

color,String: The color of the part ('red','blue','green','orange', or'purple').

agv,Integer: The agv number for the part place condition.

submission_condition: The robot malfunction will begin after the specified order has been submitted.

order_id,String: ID of the order for the submission_condition. The robot malfunction will begin once the order associated with this order ID is submitted.

sensor_blackout,Dictionary: Adds a sensor blackout challenge to the environment.

duration,Float: Determines how long the sensor blackout will last.

sensors_to_disable,List: List of sensors which will be disabled. Options are'break_beam','proximity','laser_profiler','lidar','camera', and'logical_camera'

announcement: One of the three announcement conditions. See above.

faulty_part,Dictionary: Adds a faulty part challenge to the environment.

order_id,String: Specifies the order where the selected quadrants will have faulty parts at first. If faulty parts are removed and replaced with new parts, the new parts will be non-faulty.

quadrant{n},Bool: Specifies if quadrantnhas a faulty part or not. For example, ifquadrant1is set to true, any first part placed in quadrant 1 is faulty.

1# Trial name: example.yaml

2# ARIAC2024

3# Author: Justin Albrecht

4# 2024-01-03 14:23:37

5

6# ENVIRONMENT SETUP

7

8time_limit: 500

9

10# KITTING TRAYS

11

12kitting_trays:

13 tray_ids:

14 - 2

15 - 2

16 - 2

17 - 4

18 - 4

19 - 4

20 slots:

21 - 1

22 - 2

23 - 3

24 - 4

25 - 5

26 - 6

27

28# INSERT ROTATION

29

30assembly_inserts:

31 as1: pi/3

32 as2: -pi/4

33 as3: 0.0

34 as4: pi/2

35

36# PARTS INFORMATION

37

38parts:

39 agvs:

40 agv2:

41 tray_id: 0

42 parts:

43 - type: sensor

44 color: blue

45 quadrant: 1

46 rotation: 0.0

47 - type: pump

48 color: blue

49 quadrant: 2

50 rotation: 0.0

51 - type: regulator

52 color: blue

53 quadrant: 3

54 rotation: 0.0

55 - type: battery

56 color: blue

57 quadrant: 4

58 rotation: 0.0

59 bins:

60 bin1:

61 - type: sensor

62 color: green

63 rotation: pi/4

64 flipped: false

65 slots:

66 - 1

67 - 3

68 - 7

69 - 9

70 bin2:

71 - type: pump

72 color: purple

73 rotation: 0.0

74 flipped: false

75 slots:

76 - 1

77 - 3

78 - 7

79 - 9

80 bin5:

81 - type: battery

82 color: orange

83 rotation: 0.0

84 flipped: true

85 slots:

86 - 2

87 - 4

88 - 6

89 - 8

90 bin6:

91 - type: regulator

92 color: blue

93 rotation: -pi

94 flipped: false

95 slots:

96 - 2

97 - 4

98 - 6

99 - 8

100 conveyor_belt:

101 active: true

102 spawn_rate: 3.0

103 order: random

104 parts_to_spawn:

105 - type: sensor

106 color: orange

107 number: 3

108 offset: 0.2

109 flipped: false

110 rotation: pi/3

111 - type: battery

112 color: red

113 number: 5

114 offset: 0.0

115 flipped: true

116 rotation: 0.0

117

118# ORDERS INFORMATION

119

120orders:

121- id: E414303S

122 type: kitting

123 announcement:

124 time_condition: 0.0

125 priority: false

126 kitting_task:

127 agv_number: 1

128 tray_id: 2

129 destination: warehouse

130 products:

131 - type: sensor

132 color: green

133 quadrant: 1

134 - type: battery

135 color: red

136 quadrant: 2

137 - type: pump

138 color: purple

139 quadrant: 4

140- id: YTDIGV7W

141 type: assembly

142 announcement:

143 submission_condition:

144 order_id: E414303S

145 priority: false

146 assembly_task:

147 agv_number:

148 - 2

149 station: as1

150 products:

151 - type: sensor

152 color: blue

153 assembled_pose:

154 xyz:

155 - -0.1

156 - 0.395

157 - 0.045

158 rpy:

159 - 0

160 - 0

161 - -pi/2

162 assembly_direction:

163 - 0

164 - -1

165 - 0

166 - type: pump

167 color: blue

168 assembled_pose:

169 xyz:

170 - 0.14

171 - 0.0

172 - 0.02

173 rpy:

174 - 0

175 - 0

176 - -pi/2

177 assembly_direction:

178 - 0

179 - 0

180 - -1

181 - type: regulator

182 color: blue

183 assembled_pose:

184 xyz:

185 - 0.175

186 - -0.223

187 - 0.215

188 rpy:

189 - pi/2

190 - 0

191 - -pi/2

192 assembly_direction:

193 - 0

194 - 0

195 - -1

196 - type: battery

197 color: blue

198 assembled_pose:

199 xyz:

200 - -0.15

201 - 0.035

202 - 0.043

203 rpy:

204 - 0

205 - 0

206 - pi/2

207 assembly_direction:

208 - 0

209 - 1

210 - 0

211- id: 7JADKH4U

212 type: combined

213 announcement:

214 part_place_condition:

215 color: purple

216 type: pump

217 agv: 1

218 priority: true

219 combined_task:

220 station: as3

221 products:

222 - type: regulator

223 color: blue

224 assembled_pose:

225 xyz:

226 - 0.175

227 - -0.223

228 - 0.215

229 rpy:

230 - pi/2

231 - 0

232 - -pi/2

233 assembly_direction:

234 - 0

235 - 0

236 - -1

237 - type: sensor

238 color: orange

239 assembled_pose:

240 xyz:

241 - -0.1

242 - 0.395

243 - 0.045

244 rpy:

245 - 0

246 - 0

247 - -pi/2

248 assembly_direction:

249 - 0

250 - -1

251 - 0

252

253# CHALLENGES INFORMATION

254

255challenges:

256- dropped_part:

257 robot: floor_robot

258 type: regulator

259 color: blue

260 drop_after: 0

261 delay: 0.5

262- robot_malfunction:

263 duration: 20.0

264 robots_to_disable:

265 - floor_robot

266 submission_condition:

267 order_id: 7JADKH4U

268- sensor_blackout:

269 duration: 20.0

270 sensors_to_disable:

271 - logical_camera

272 - camera

273 time_condition: 100.0

274- faulty_part:

275 order_id: E414303S

276 quadrant1: true

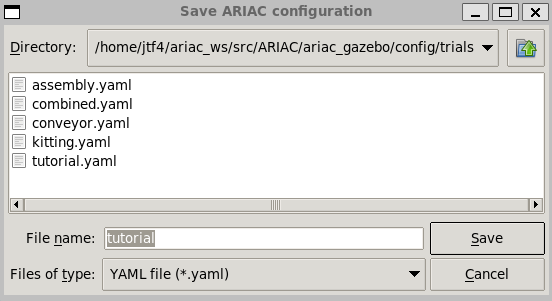

Trial Generator GUI

Instructions to Start the Trial Generator

To run the ARIAC configuration GUI, first, install the dependencies with

cd ~/ariac_ws && pip install -r src/ARIAC/ariac_gui/requirements.txt

After the dependencies are installed, run the GUI with

ros2 run ariac_gui trial_generator

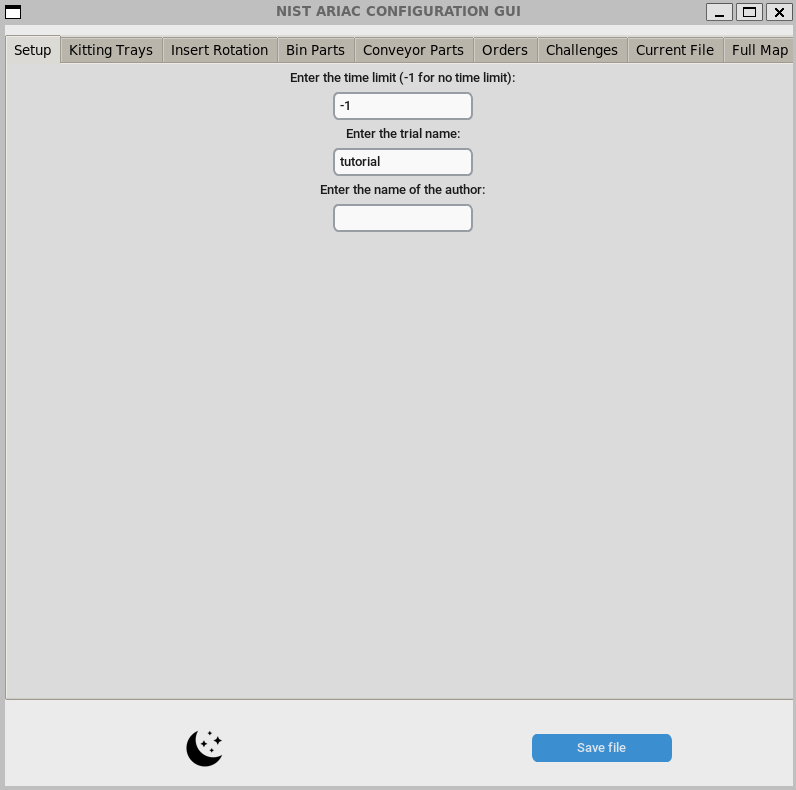

Setup Tab

The first tab of the GUI lets you edit the header of the configuration file. This includes the time limit, the trial name, and the name of the author.

Fig. 3 Setup Menu

Kitting Trays Tab

The second tab is the kitting trays menu. This menu lets you choose the kitting tray in each of the slots. When a kitting tray is selected, the kitting tray with the correct fiducial tag appears on the tables in the GUI.

Fig. 4 Kitting Trays Menu

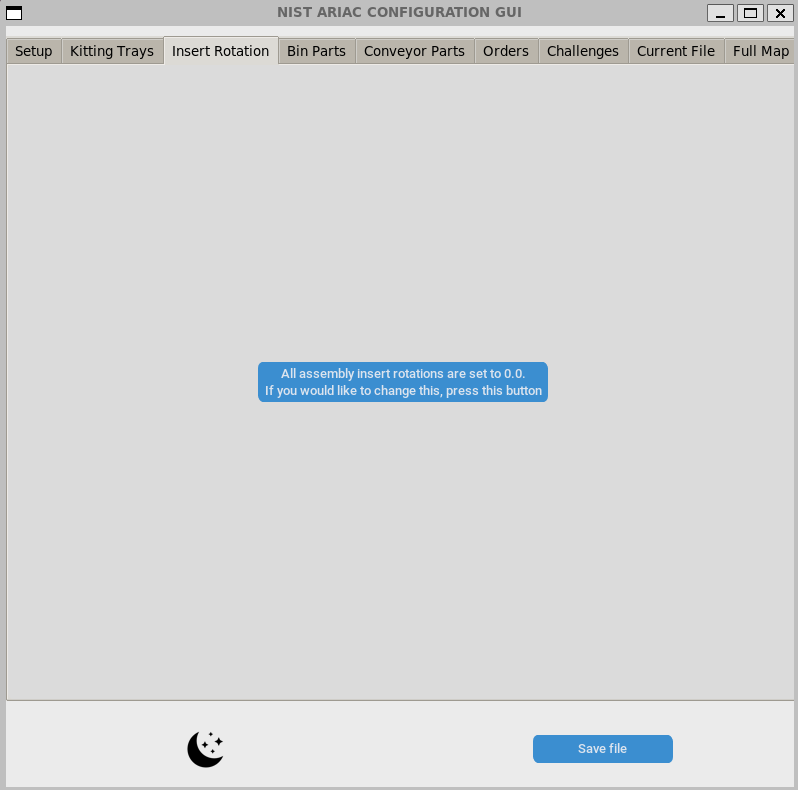

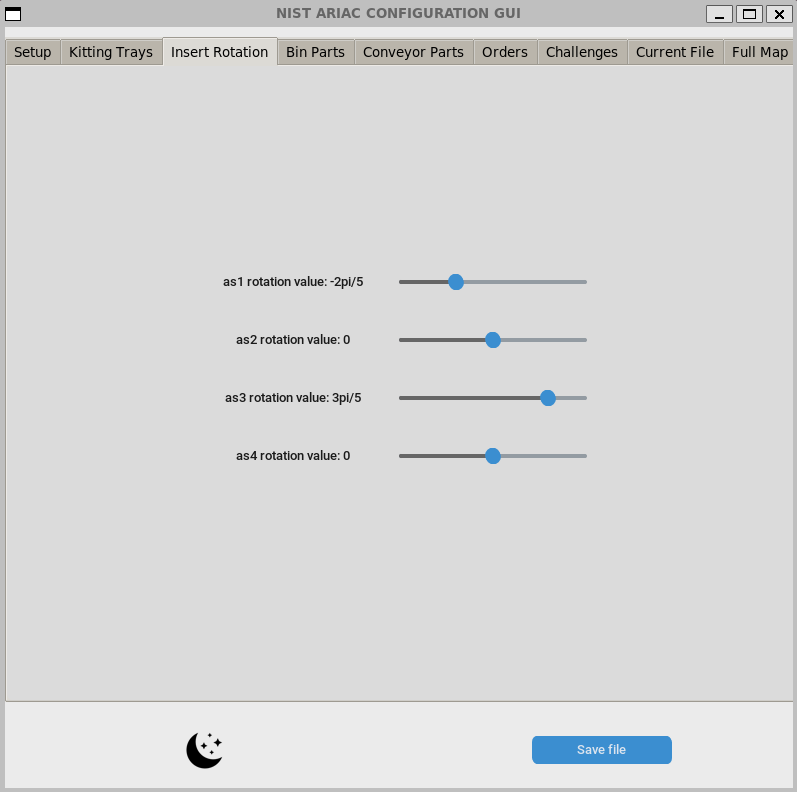

Assembly Insert Rotation Tab

The third tab is the assembly insert rotation menu. At first, as long as a file with non-zero assembly insert rotations is not loaded in, this menu will be a button which states that all the inserts are currently set to 0.0.

Fig. 5 Assembly Inserts Initial Menu

If this needs to be changed, press the button and four sliders appear, which allow you to change the rotation of each of the inserts.

Fig. 6 Assembly Inserts Slider Menu

Bin Parts Tab

The fourth tab is the bin parts menu. At the top of this menu, there is a dropdown menu which changes the bin being edited. On the left half of this menu, a diagram of the bin shows up with each slot acting as a button. If there is a part there, the button will be an figure of the part with the correct rotation. Clicking on a part allows it to be edited. If there is no part there, the button will be a plus sign. If this button is clicked, the add part menu will appear.

On the right half of the menu, is a minimap which shows each of the bins. The one currently being edited will show up in blue and the others will be white. This minimap also shows the parts currently on each bin. Under the diagram and the minimap, there are two buttons. The top button allows for multiple parts to be added at the same time. The second button clears the selected bin.

Fig. 7 Bins Menu

Conveyor Parts Tab

The fifth tab is the conveyor parts menu. The top half of this menu has the basic conveyor settings, like spawn rate and whether the order is random or sequential. Under these options, there is an add part lot button, which adds parts to the conveyor belt. Under these settings, there is a scrollable sub-window with a list of the part lots currently on the conveyor belt. This list has buttons where the part lots can be edited or deleted.

Fig. 8 Conveyor Parts Menu

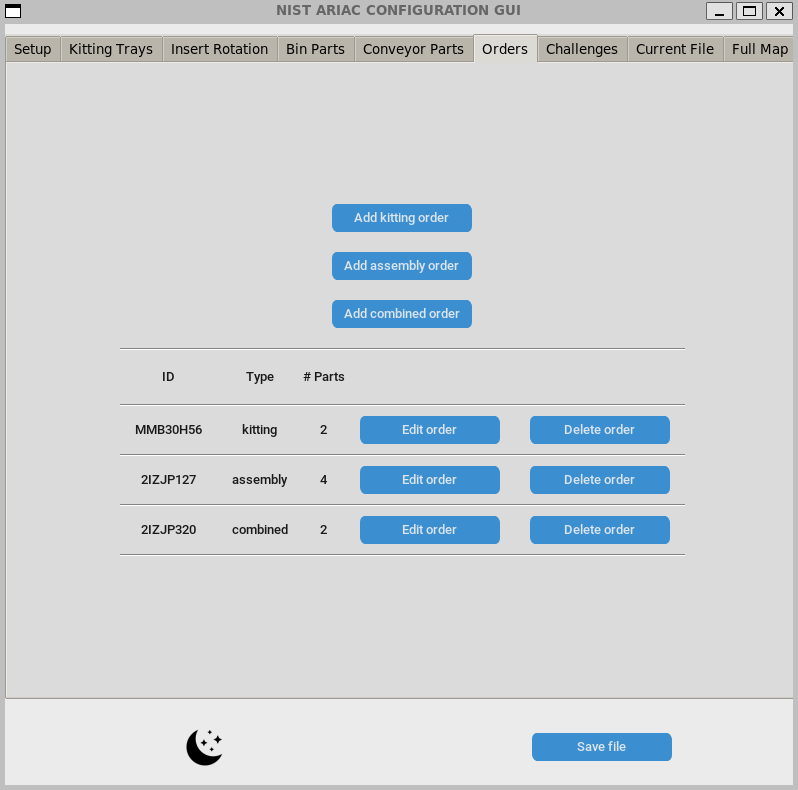

Orders Tab

The sixth tab is the orders menu. There are three main buttons in this menu, the “Add kitting order”, “Add assembly order”, and “Add combined order”. If any orders have already been created, a menu will show up under these buttons with edit and delete buttons. If no kitting trays have been selected, the GUI will not be able to create a kitting order.

Fig. 9 Orders Menu

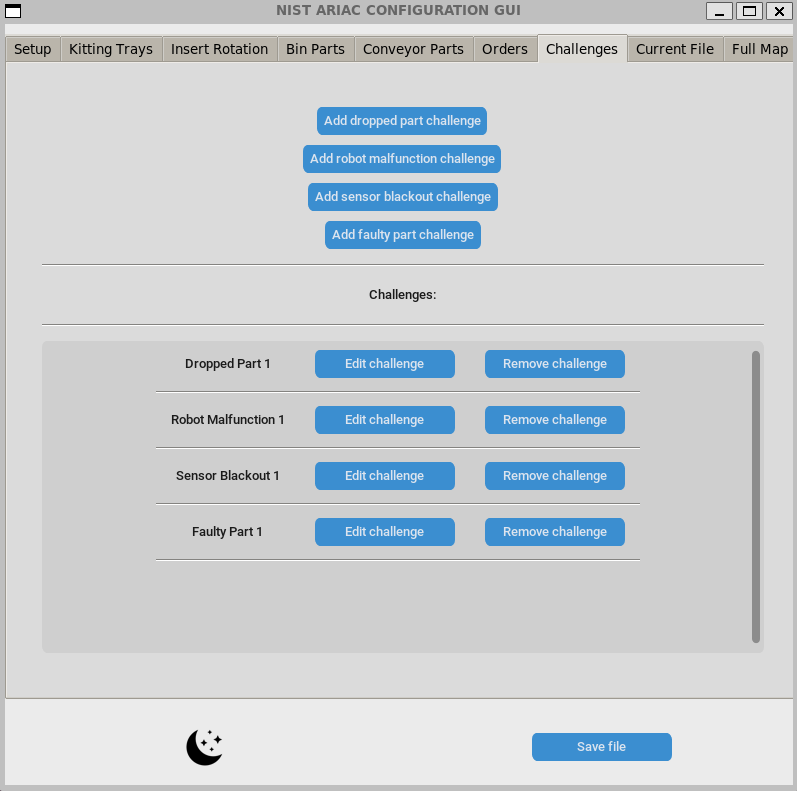

Challenges Tab

The seventh tab is the challenges menu. This menu can add any of the challenges available in the configuration file. Once challenges are made, they appear in a scrollable sub-window with edit and delete buttons for each of the challenges.

Fig. 10 Challenges Menu

Current File Tab

The eighth tab shows the current file in yaml format. This is updated live any time a change is made.

Fig. 11 Current File Tab

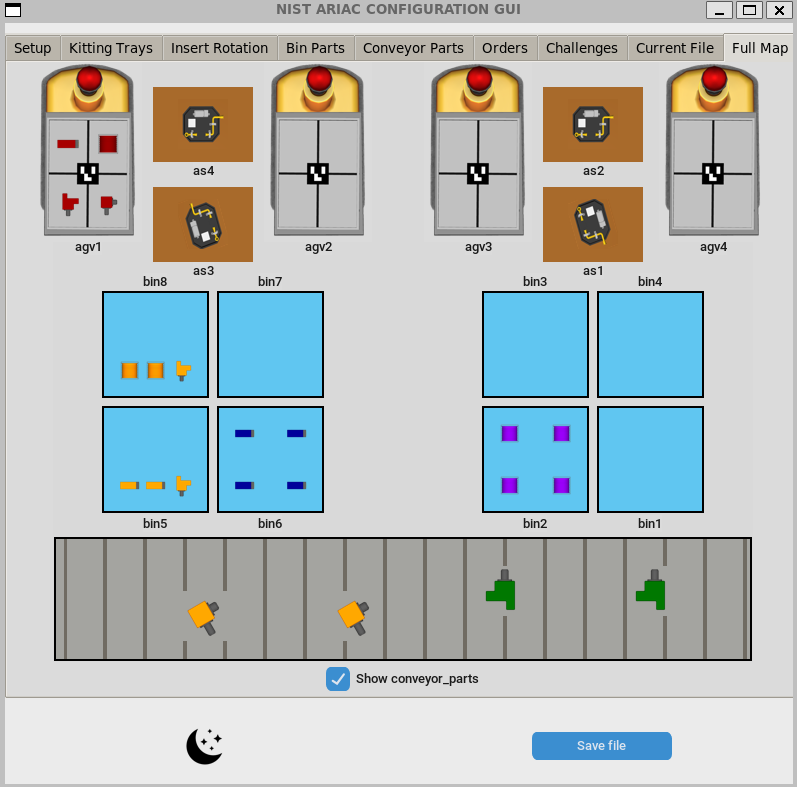

Map Tab

The final tab is a map of the environment which shows each every part present on the AGVs, bins, and conveyor belt. It also shows the rotation of the assembly stations. To show the conveyor belt parts, set the “Show conveyor_parts” checkbox to true. The parts will move across the conveyor belt. Any time a part is added, edited, or deleted on the conveyor belt, the checkbox will automatically turn off.

Fig. 12 Full Map